NAVIGATION

-

NAVIGATION

- HOME

- ABOUT US

- PRODUCTS

- TEST EQUIPMENT

- PROCESS

- HONOR

- NEWS

- CONTACT US

Professional manufacturer of casting and hardware parts

Professional manufacturer of casting and hardware parts

Years of hard work and craftsmanship in the field of precision casting

factory outlet

Customized by drawing

cheap and fine

Fast Shipping

Company strength

Company strength

Complete international and domestic standards, customizable according to your needs

The team has 20 years of processing experience, and the technical backbone is more than 10 years of proficient hands

For long-term stable and large-scale products, our company adopts fully automated robot production to reduce labor costs and stabilize production

The machining quality of the CNC center is stable, and the machining accuracy can reach between 0.1 and 0.2MM

Fully inspect the size of processed products for shipment, ensuring that all products received by customers are qualified

Quality first

Quality first

Resolutely say no to the following actions

Without self-developed molds and independent CNC processing capabilities, all processes and processes rely on outsourced processing, quality cannot be monitored in place, and delivery times cannot be guaranteed.

The production process is not standardized and rigorous: the process is not perfect, there are no detailed links and quality control, and the forging embryo is rough and indiscriminate.

After processing, there is no visible light or burrs left on the casting. The products we produce and process have a clean and tidy appearance, precise dimensions, glossy and burr free appearance, and customized packaging according to needs

PRODUCT SHOW

PRODUCT SHOW

Do a good job in every product detail, just because we understand your needs better

WHY CHOOSE US

WHY CHOOSE US

Let you find the safety products you need here, providing fast, thoughtful, reliable, and satisfactory services

IIntroducing professional production equipment and scientific management to ensure product quality, with multiple efficient machines, mainly producing and processing hardware such as stainless steel and aluminum alloy.

We have a modern factory building and a professional production and processing team, which can customize suitable products and a complete set of casting and processing solutions according to the specific requirements of customers.

Advanced imported casting equipment, testing equipment, and reliable castings and casting materials, achieving a high yield rate.

Introducing excellent mold making and mold surface treatment technology, the finished product has a uniform density, is not prone to blistering, fracture, or deformation.

Having an experienced quality inspection team, we ensure the quality of our products is checked layer by layer. From production to shipment, we need to go through 6 full inspection processes to ensure zero error before leaving the factory.

Having unique technology and a group of high-tech talents, able to design and manufacture according to the special requirements of customers.

The production and inventory are sufficient, and delivery can be made on the same day for urgent needs. The shipment is on time and we will serve you 7 * 24 hours a day, ensuring a response within 2 hours.

A professional delivery team and logistics distribution system provide you with integrated processing and delivery services, and professional customer service is one-on-one to provide you with thoughtful services.

APPLICATIONS

APPLICATIONS

Monitor and inspect every step to ensure the quality of die castings before leaving the factory

Dongguan Pingye Machinery can provide customers with stainless steel, titanium alloy, aluminum alloy, copper, iron and other hardware products of various brands and material requirements. We can provide customers with higher quality hardware and accessories, and the processed products are fast, precise, and accurate, highly praised by customers.

VIRE MORE

CUSTOMIZATION PROCESS

CUSTOMIZATION PROCESS

We specialize in providing customers with a one-stop solution, covering all aspects of design and production

Consultation

DESIGN

Proofing

produce

delivery

After Sales

Dongguan Pingye Machinery Co., Ltd., located in Dongguan City, was founded in December 2016.

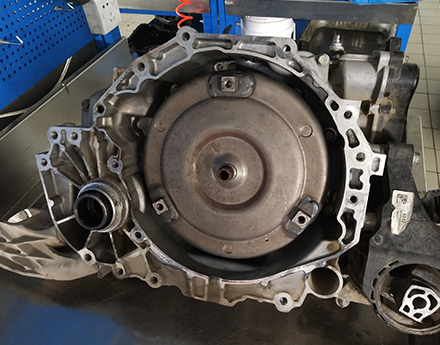

Hirano Machinery specializes in developing mass production plans for various metal castings and manufacturing various precision jigs, as well as precision parts processing and specialized in the production of automotive environmental protection edge EGR

(exhaust gas treatment system) and final inspection of various products before shipment and so on.

HONOR SHOW

HONOR SHOW

Successively obtained ISO9001 and ISO13485 certifications to ensure product quality is certain to pass the standards

Customer Stories

Customer Stories

20 years of industry accumulation, with service experience in Fortune 500 automotive enterprises

NEWS CENTER

NEWS CENTER

Provide you with industry news information and learn more about the dynamics of aluminum castings

In September 2023, the general manager and his delegation visited Komatsu in Koki Prefecture, Japan, Sekiko Industries in Fukushima Prefecture, Hirano Manufacturing Institute in Iwate Prefecture, and Mitsubishi in Saitama Prefecture to learn about the production of three companies factories.

2023-11-07The process of precision component processing has extremely strict requirements. Any slight carelessness during processing can cause the workpiece error to exceed the tolerance range, requiring re processing or declaring the blank scrapped, greatly increasing production costs. Therefore, today Shenzhen Lianrongda Industrial Co., Ltd. will talk about the requirements for precision component processing? Can help us improve production efficiency.

2023-05-02CNC lathe machining is a general term for machining parts on CNC machine tools. Computer controlled machine tools are collectively referred to as CNC lathes in the mechanical processing industry, and both computers designed specifically to control CNC machine tools and general computers are referred to as CNC systems. CNC lathe machining is widely used in the precision parts processing industry. Next, lets introduce the process characteristics of precision parts processing on CNC lathes:

The fault curve can conceptually represent the relationship between the fault rate and time of CNC machine tool processing. Because this curve is bathtub shaped, it is often called Bathtub curve curve. It divides the service life of CNC machine tools into three stages, namely early failure period, unexpected failure period, and loss failure period. In the early stages of faults, the machine tool failure rate follows a negative exponential curve function.

When using a CNC lathe to process hardware, all rotating parts that can be clamped on a regular lathe can be processed on the CNC lathe. However, CNC lathes have the characteristics of high machining accuracy, linear and circular interpolation, and automatic transmission in the hardware processing process, and their process range is much wider than ordinary machine tools.